Sampi sorter ϡ

Advanced Sorting Solutions for Agriculture

Product Overview

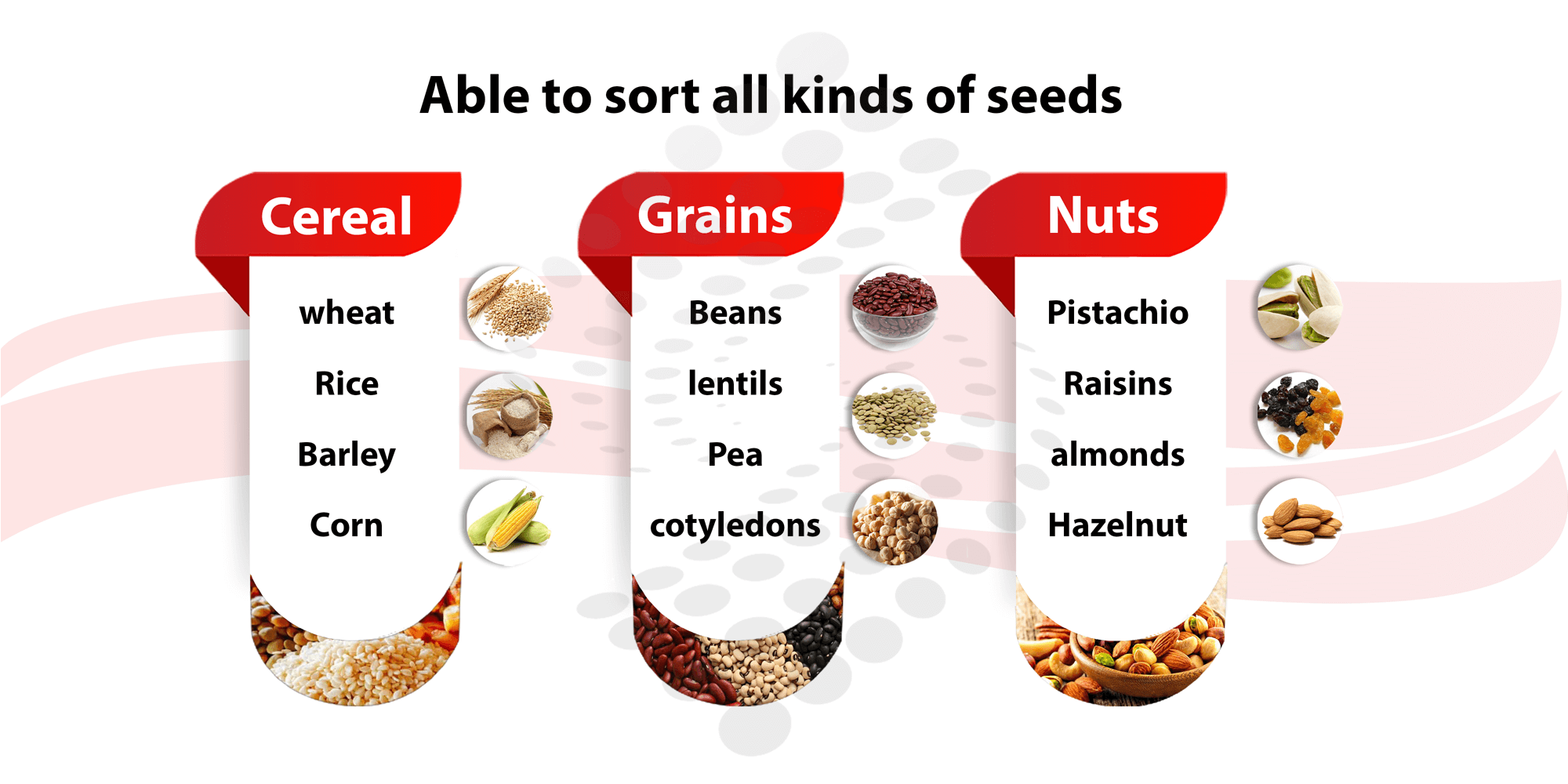

The Sampi sorter is a cutting-edge sorting machine designed to meet the diverse sorting needs of the agricultural industry. With its advanced technology and innovative features, it enables efficient sorting of various products such as nuts, grains, dried fruits, chips, and more

About Sampi Sorter

The Sampi Sorter is an advanced sorting solution designed to efficiently separate grains and agricultural products based on various visual characteristics. With its cutting-edge technology and artificial intelligence capabilities, the Sampi Sorter ensures high precision and accuracy in the sorting process, leading to improved quality and productivity

How Sampi Sorter Works

In the Sampi sorter, the grains are transferred to the feeder either through a conveyor or manually. A powerful blower connected to the feeder removes some fine contaminants such as dust and hair from the product during sorting. The Sampi sorter's feeder is designed and manufactured using advanced vibrators, allowing the speed to adjust for transferring grains onto the conveyor. The grains are continuously and evenly placed on the conveyor with an appropriate distance

The grains move at a certain speed on the conveyor. When they reach the end of the path, they separate from the conveyor and remain suspended in the air as they pass in front of advanced sensors, projectors, and cameras. At this moment, multiple images are captured of each grain from different angles, and various visual features of each grain are identified through image processing

The artificial intelligence of the machine matches the different visual features of the grain with the training it has received to identify standard grains based on size, shape, color, and morphology. The device classifies the grains into desired and undesired categories according to user settings

Next, the grains pass in front of a line consisting of several compressed air nozzles. If a grain falls into the undesired category, the corresponding nozzle activates and diverts the grain from the path of other grains using a jet of air, sending it to the output for undesired grains. If a grain falls into the desired category, no nozzle acts on it, and it is directed to the output for desired grains. The system strives to have the gentlest possible contact with the grains to minimize damage and loss. In gravity-based sorters, such as for pistachios, the grains collide with each other at high speeds at the end of the path, sometimes causing the separation of their shells, which results in loss of product. However, in the Sampi conveyor sorter, the energy of the grains is approximately one-fourth of that in the intelligent pistachio sorter

Classification Parameters

- Utilizes artificial intelligence and deep learning algorithms

- Conveyor designed to meet European food industry standards

- Remote monitoring capability

- Easy-to-clean design

- 24/7 operation

- User interface with different access levels (administrator, operator)

- No water requirement

- Emergency stop button and advanced safety features

Key Features

- Classification based on size, color, shape, and morphology

- Sorting based on specific seed characteristics (e.g., pistachio shell, raisin tail)

- Non-destructive sorting to prevent product damage

- User-friendly touch interface for easy operation

- Food-grade stainless steel and aluminum structure

- Real-time quality statistics and performance reports

- Advanced feeder with electronic rate control

- Laser and image processing-based detection

Advantages of Sampi Sorter over Traditional Sorters

Many traditional sorting systems face several challenges that can hinder efficient and effective sorting. However, with the advanced technology and intelligent design of the Sampi Sorter, these problems are effectively addressed.

- Inability to separate high-quality agricultural products from substandard ones in an advanced manner

- Product damage caused by mechanical and outdated sorting technologies

- Lack of standardization and consistency in sorting results due to manual sorting and uncertainty

- Limited time to present agricultural products to the market before their quality declines

- Issues with human interaction in sorting processes and related hygiene concerns

With the Sampi Sorter, these challenges are overcome, enabling efficient, standardized, and high-quality sorting of various products.

Sourcin Sorter Offers the Following Advantages:

- Minimization of waste and losses

- Improved organization and precise control of input and output in the production line (production line management)

- Production line reports and analyses

- Product tracking and provision of statistical reports

- Higher accuracy and preservation of product integrity compared to chute-type sorters due to the use of conveyor

- Creation of qualitative and financial added value based on product classification

- Assurance of consistent and high-quality sorting results with no subjective worker interference

- Easy definition of the target product in the machine

- Maintaining product integrity during the sorting process

- Reduction in production costs

- Decrease in complaints and returns of manufactured products